Grain refinement in MSG welding of aluminum alloys by surface-coated additives for initial solidification crack reduction

Funding: DFG Duration: 10/2019 to 09/2022

Abstract

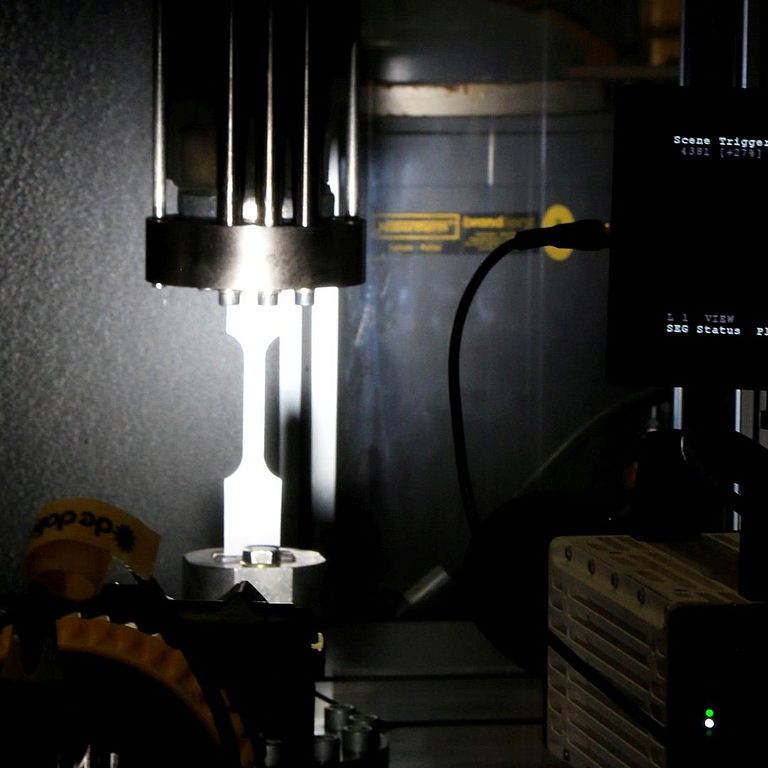

The research project pursues the goal of transferring the known grain-reducing effect of certain elements during the solidification of aluminum alloys to the weld metal during fusion welding. By coating the filler wires with nucleating elements, such as titanium, these are to be introduced into the weld metal and thus contribute to grain refinement. The formation of fine grains in the weld metal is expected to significantly reduce solidification cracks. Furthermore, it is to be investigated whether grain refinement can be transferred to age-hardenable alloy types which are extremely sensitive to hot cracking. In addition, a precipitation hardening of the weld metal is to be realized in order to be able to achieve the positive effect on the strength properties and to partially compensate for the drop in strength in the heat-affected zone by a supporting effect of the now stronger weld. The metal-glass technique will be used to investigate the nucleation mechanisms of the coating elements in the weld metal. This makes it possible to virtually freeze the state of the molten metal and to visualize the distribution of the solidification nuclei in the scanning electron microscope using energy-dispersive X-rays. This technique is intended to increase our knowledge of the formation of the weld metal during MSG welding of aluminum materials, since other solidification nuclei resulting from the welding process can be made visible in addition to the coating elements. A further objective is therefore to derive laws governing the formation of the microstructure in the weld metal by the layer of grain-reducing elements on the modified filler metals. General relationships between grain size, mechanical properties, coating thickness and/or composition are to be worked out. High-speed recordings and the functional relationship between current and stress values can be used to determine how the welding process is influenced by the coating of the wire electrodes. This includes the influence of the arc length, the droplet transition and the penetration behavior. Here, too, the aim is to derive general laws.