Development of advanced MAX-phase coatings (eMAX) for the protection of engine components under high temperature jet wear load (eMAX/Hot)

Funding: ZIM

Duration: 04/19 - 03/21

Abstract:

The demands on engine components in aviation are constantly increasing. The goals of reducing CO2 and NOx emissions as well as noise levels can only be achieved by using new materials. These materials must be lighter, more temperature resistant and at the same time damage tolerant and predictable. In many application scenarios, these components require the additional protection of coatings in order to achieve sufficient service life, especially if the components are exposed to direct erosion. Although high sand and dust concentrations occur during flight operations, especially during take-off and landing procedures in arid areas, a considerable amount of particles are also carried into the atmosphere by wind and are widely spread. Material removal can cause significant changes in the geometry and surface quality of the blades, which can ultimately lead to performance losses in the engine.

Due to the wear and tear with varying degrees of intensity in different flight regions, very short maintenance intervals are currently used in aviation. In addition, slightly worn turbine parts are replaced in order to ensure a very high level of flight safety. Therefore, an increase in the service life of all turbine parts by only 10% would be of immense economic interest and, according to the aviation industry, would represent a great potential for cost savings. An innovative approach are therefore modern coating processes with thin film layers according to the MAX-phase principle. These phases have been described in science, but the transfer to fields of application is largely missing. Furthermore, an adequate testing technique for such applications has not yet been standardized. Here, too, the development of adequate tests is of great economic interest.

The aim of this project is to extend the range of these technically useful phases, especially with regard to erosion resistance at high temperatures. The project is therefore divided into two sub-projects:

- Development of novel eMAX targets together with manufacturing and bonding technology

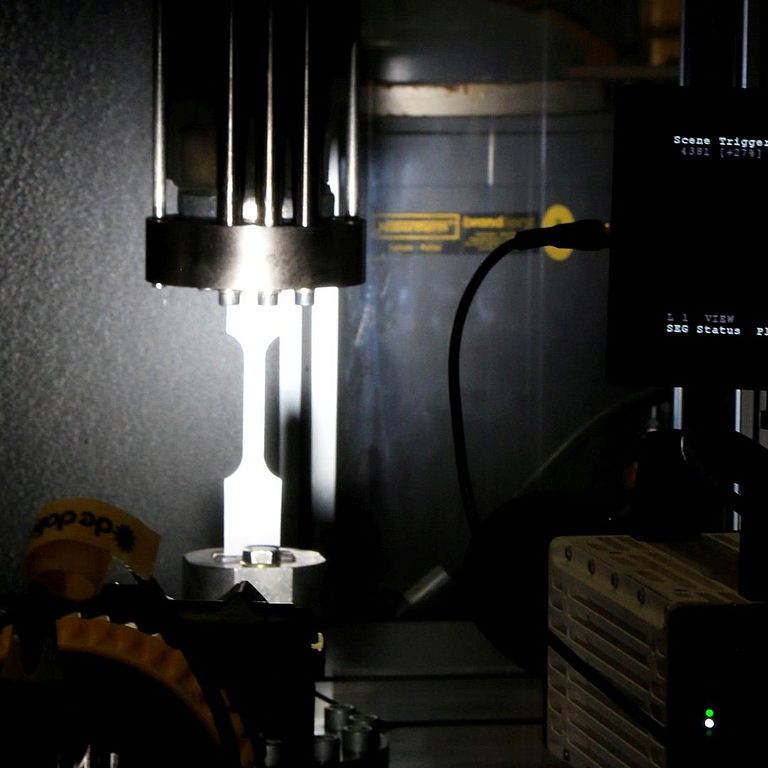

- Development of coating process framework conditions and conversion process as well as the development of a suitable test and investigation strategy for such coating systems

The MAX-phase similar layers are to be sputtered from a compound target using the PVD process. Subsequently, these layers are heat treated to locally influence the properties. For example, primarily ceramic properties are to be generated for applications with erosive wear. The thin-film coatings are further tested for wear resistance using various test methods. In particular, jet wear tests are being carried out at elevated ambient temperatures of up to 700 °C to qualify the behaviour of the coatings with regard to engine applications.