Development of wear protection systems for aluminium die-cast components using novel alloys and manufacturing strategies

Funding: ZIM Duration: 01/20 - 12/21

Abstract: The aim of the research project is the development of wear protection solutions for aluminium die cast components. This shall be realized by the development of novel alloys and the weldable coating of inlays.

Using the EHLA process, the components are to be coated with a powdery welding filler metal which combines high deposition rates due to high feed rates with low line energy. This process has not yet been used for internal pipe coating. An adaptation of the laser optics, the weld metal feed and the traversing mechanisms is necessary. Furthermore, the production of the parts is to be adapted to near net shape and load-adapted coatings.

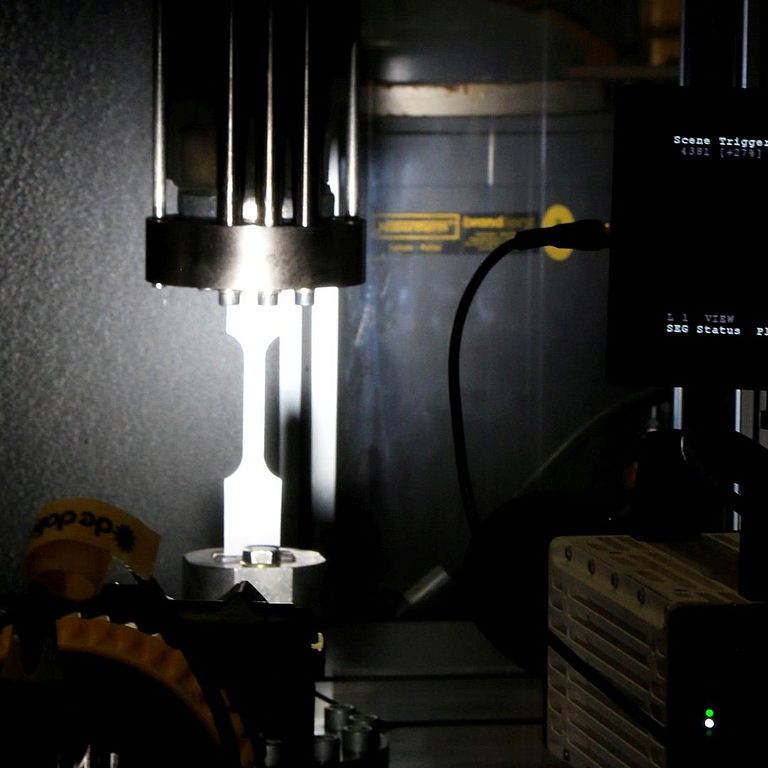

The planned alloys are cobalt and chrome vanadium alloys. These alloys should offer a higher resistance against the combined chemical and abrasive load. The alloy development is supported by the qualification of the materials in a tribologically adapted test procedure. Besides the tribological properties, the examination of the weldability is of central interest.