Increased electrode service life in resistance spot welding of aluminium alloys by means of applied diffusion barrier coatings

Funding: DFG Duration: 09/2021 to 10/2024

Abstract

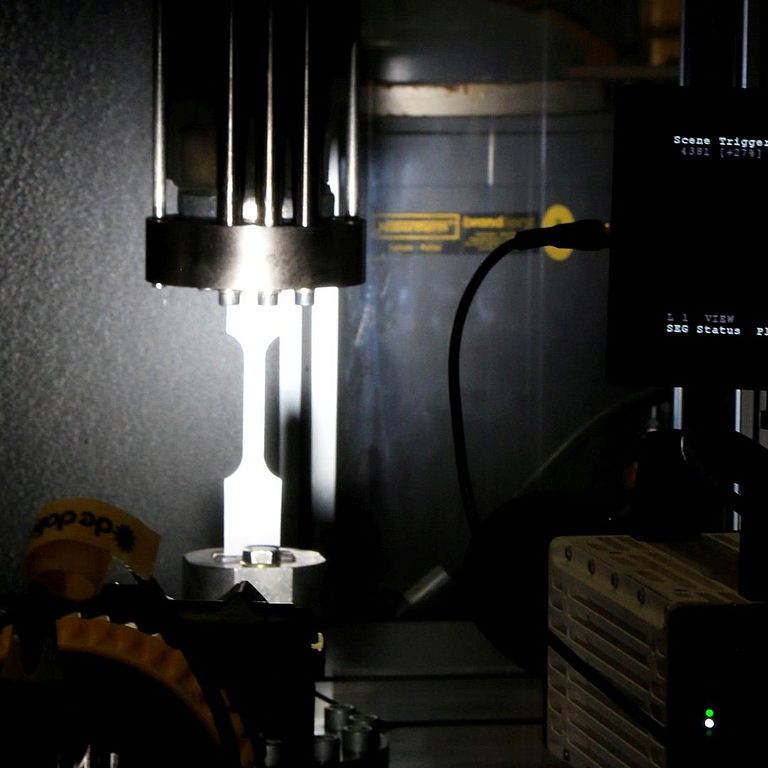

During resistance spot welding of aluminium alloys, considerable damage occurs to the electrode working surfaces after just a few welding cycles. The damage mechanisms at work are due to the natural oxide layer of the aluminium sheets. The electrode force generated only leads to insufficient penetration of the electrically insulating in the electrode-sheet contact. For this reason, high current densities and high local temperatures occur in the welding process, which accelerate diffusion processes in the Cu-Al contact. This leads to the formation of intermetallic phases in the material area of the electrode. The brittle intermetallic phases break out under high mechanical stress or are torn out by the molten connection with the sheet materials as a result of electrode movements. This loss of material at the electrodes is known as pitting and leads to a continuous deterioration in the desired quality criteria of the welded joints. The result is a low electrode level, which limits the economic efficiency of resistance spot welding with aluminium alloys.

The aim of this project is to increase the achievable electrode level by structuring the electrode working surfaces and creating thin-film diffusion barriers using physical vapour deposition. The structuring should help to penetrate the oxide layers of the aluminium sheets and increase the proportion of electrically conductive contact surfaces. This should avoid local current density maxima and reduce the thermal load on the electrodes. The different influences of structuring through particle blasting and machining processes are being investigated. As a further approach, thin-film diffusion barriers in the thickness range of 1 to 3 µm are to be created on the electrodes to prevent direct Al-Cu contact. To this end, monolithic metallic coating materials (Ni, W) and electrically highly conductive ceramic coating materials (TiB2, TiC) will initially be investigated. Later on, customised composite systems will be created from qualified individual layers. The application of thin-film diffusion barriers is intended in particular to prevent the formation of intermetallic Al-Cu phases and to maintain the electrical, thermal and mechanical properties of the electrodes.

The combination of electrode structuring and diffusion barriers is analysed in level studies. It is shown that these modified working surfaces reduce the damage mechanisms and can contribute to an increase in the electrode level. In addition, the quality limits of the welds can be significantly improved compared to the reference condition.