Jet wear test

Jet wear test

Blast wear is an erosive stress type that occurs when particles in a medium strike a surface. The medium can be liquid or gaseous and the mass removal during jet wear is significantly influenced by the angle of attack. Depending on the angle, a distinction is made between sliding jet wear, inclined jet wear and impact wear.

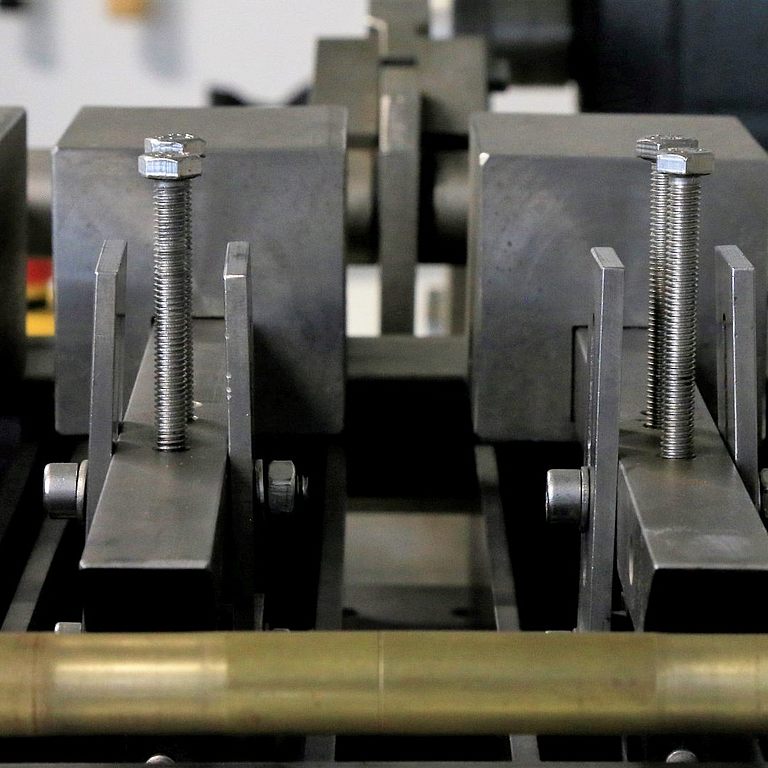

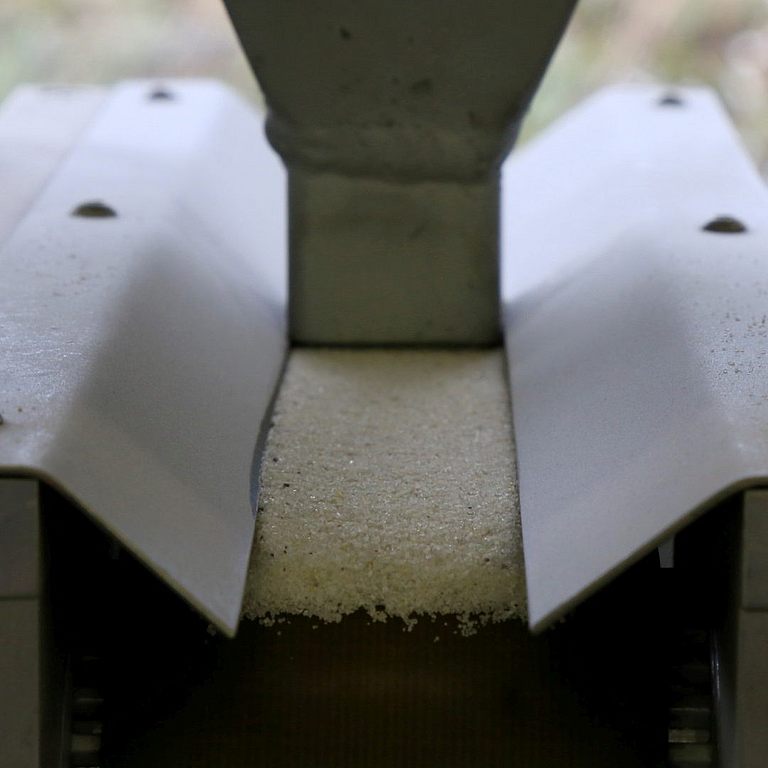

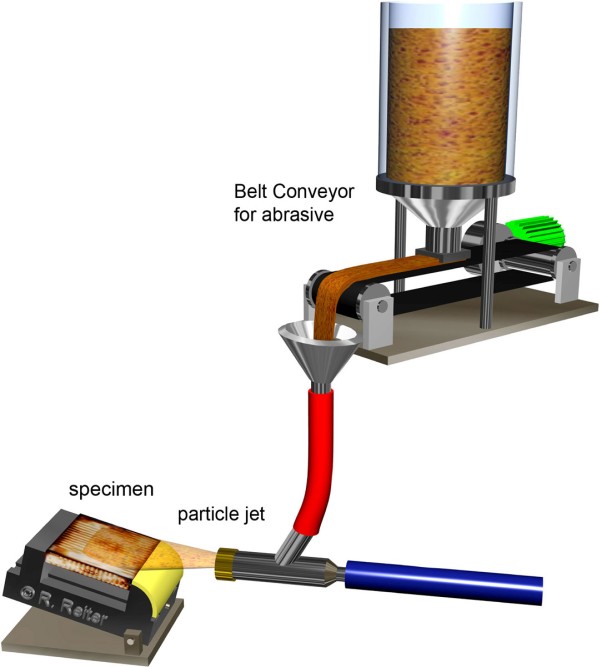

This form of wear occurs in many industrial applications, such as pneumatic conveyor technology, cement production, power plants, etc. The wear occurs here in the conveyor lines. Especially in pipe bends all three types of wear come into play. In order to be able to simulate these different influences, it is possible to install the samples at different beam angles on the beam wear test bench. The beam wear facility at ISAF is operated according to the injector principle. Here the carrier medium is blown at high pressure through a nozzle into the mixing chamber. The suction creates a negative pressure, which ensures that the solid matter is sucked in from a second line and accelerated in the flow, Figure 1.

To extend the spectrum of the solids to be blasted, nitrogen can also be used as a carrier medium. The abrasive is not reprocessed in this test and is only used once to make the test reproducible. The test stand is modularly designed and can be converted to suit the user's specific requirements.